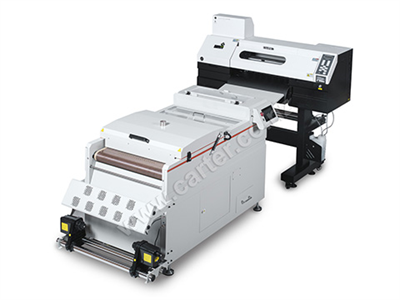

DTF PRINTER SHAKER SYSTEM 60cm

OR6202

End of Line Sale Price! A cancelled order to the Pacific Islands presents an opportunity to get this DTF workhorse for a bargain. It wont last long at this price!

The CNZOR6202 DTF printing system is a fully automated system designed to create DTF transfers

Finance Options available.

DTF (Direct To Film) is an alternative printing process to DTG, White Toner Transfers and HTV. Once heat pressed the water-based ink is transferred to the garment in just seconds.

Prints can be applied to Cotton, Polyester, Nylon, Denim and much more. DTF is taking the world textile industry by storm. It has quickly become one of the most popular technologies for garment decoration.

Say goodbye to Weeding, Pre-treating, B-Papers and being limited to certain substrates. Say hello to DTF!

The System comes complete with Laptop or PC pre-loaded with Cadlink Digital Factory DTF Software. Our qualified technician will install the system and provide onsite training.

Installation and delivery costs may vary depending on location.

Check at the video at the bottom of this page to see this unit in action at our warehouse.

Warranties are not transferable

Was: $22,750.00

Now:

$18,999.00

Excl. GST

Product info

- 2 x i-3200 Printheads CMYK WWW

- Media Width 600mm

- Climate control set to 20-25 degrees Celsius and 40 - 60% humidity

- Vent to the outside. Fumes are harmful.

- Speed 30+ 250mm x 250mm per hour (6 pass) 720 x 1200dpi

- Shaker unit: A/C 20 amps 1 Dedicated circuit

- Printer: AC 10 amps

Dimensions

- Printer: 1625 wide x 865 deep x 1450 high

- Dryer: 1015 wide x 2340 deep x 1040 high (Will not fit through a standard door frame)

- Estimated Entire Footprint for the Setup: 1625 wide x 3350" deep

Warranty

Printer and Shaker unit - 12 months warranty

Printheads - 6 Months warranty